[ad_1]

Should you run an workplace provide retailer and must fill up on notebooks, you will purpose to search out the very best quality notebooks on the most reasonably priced worth in bulk.

This entails researching varied pocket book suppliers, evaluating prices, evaluating product high quality, and deciding which provider to decide on.

When finishing these actions, you’re beginning the supply to pay (S2P) course of, which is one thing each enterprise goes by way of when working with suppliers.

Preserving bills low whereas sustaining regular income streams is significant to the success of any such enterprise, and optimizing the S2P course of is among the best methods to scale back enterprise prices.

Listed here are some questions that this text will try and reply now –

- What’s supply to pay?

- What does the supply to pay workflow appear like?

- Is S2P the identical as P2P?

- The way to optimize the source-to-pay course of?

What’s Supply to Pay?

Supply to pay, frequently known as S2P, is all the end-to-end technique of deciding whether or not you want a sure services or products, discovering the perfect provider to work with, initiating the procure-to-pay course of, making a purchase order, and receiving the products in query.

Whereas the supply to pay course of could seem to be it’s very transactional, and components of it are, but it surely’s additionally extremely depending on vendor relationships, sensible strategizing, and fixed enchancment.

We are going to stroll by way of all of the steps of the supply to pay course of intimately under.

Steps in Supply to Pay Course of

In case your sourcing workforce basically has a guidelines of every little thing that must be accomplished all through the supply to pay course of, they’re much less prone to miss something, expose your small business to threat, or miss out on a helpful sourcing alternative.

Even additional, standardizing source-to-pay motion gadgets makes it extra doable to trim the fats from the method, discover synergies in your small business, and implement a supply to pay system that allows course of automation and streamlines provider onboarding.

Listed here are important steps required within the S2P course of:

1. Demand

A service or product should be wanted by the enterprise. Alternatively, a necessity for a cheaper price or higher phrases may create the demand.

Think about a producing firm that realizes it must improve its manufacturing line to fulfill growing buyer calls for. The operations workforce identifies a requirement for brand new equipment that can improve effectivity. This creates the demand.

2. Sourcing

Potential distributors within the provide chain are situated and evaluated. This may be achieved utilizing software program platforms that deal with massive quantities of knowledge on historic spending, market tendencies, and firm objectives for eSourcing.

After thorough analysis, they shortlist a number of distributors who meet the corporate’s high quality and compliance requirements. Distributors that move minimal requirements can then be cataloged in a seamless onboarding course of.

3. Making ready a Bid

RFx paperwork are assembled, responses are obtained from suppliers, and saved in an eSourcing portal. RFx supplies could embody requests for info (RFIs), proposals (RFPs), and quotes (RFQs).

4. Choice Making

On this step, candidates have to be reviewed. Some can be chosen, and others is not going to.

Usually, the workforce evaluations all of the submitted proposals, evaluating them based mostly on varied standards equivalent to value, high quality, and the distributors’ supply and assist capabilities.

After cautious consideration, they slender down the choices and select essentially the most appropriate vendor that provides the perfect worth for cash.

5. Contract Administration

The chosen vendor is added to the corporate’s provider administration database. The procurement workforce then negotiates the ultimate pricing, cost phrases, and repair agreements. As soon as each events agree, the contract is ready and set for signing.

6. Contract Signing

With all phrases agreed upon, the contract doc is signed by each the manufacturing firm and the equipment provider, formally sealing the deal.

7. Transition to Procure to Pay

The signed contract is handed over to the procurement workforce, which is able to handle the following buy orders and interactions with the provider.

8. Procurement

The procurement workforce points a purchase order order for the brand new equipment, detailing all agreed specs and phrases. They preserve communication with the provider to make sure that the order is processed and delivered on time.

9. Accounts Payable Bill Processing

As soon as the equipment is delivered and put in, the provider sends an bill. The accounts payable workforce verifies the bill towards the acquisition order and supply paperwork, ensures all particulars are right, and processes it for approval and cost.

10. Funds

Lastly, the accounts payable division processes the cost in line with the agreed phrases, reconciling it within the firm’s monetary data and informing the provider concerning the cost standing, thus concluding the source-to-pay course of.

By following these steps of their workflow, companies can guarantee a streamlined and environment friendly source-to-pay course of.

Supply to Pay vs. Procure to Pay

S2P and P2P should not the identical factor; the P2P course of is embedded within the S2P course of. Briefly, the S2P course of is bigger; it encompasses extra steps than the P2P course of. The P2P course of is a subset of sure steps throughout the S2P course of.

S2P begins the second {that a} enterprise chief or worker decides a brand new good or service is required from a provider. It then strikes to researching suppliers, assessing costs, sending info requests, finalizing provider choices, creating buy orders, receiving the merchandise, and fulfilling bill funds. It might probably take weeks and even months to get by way of the supply to pay course of in its entirety.

The P2P course of, then again, begins after a provider has been chosen. The procurement workforce is handed the baton from the sourcing workforce and continues to work by way of the procurement actions of the S2P course of. These embody managing buy orders and buy requisitions, monitoring product supply timelines, making certain the receipt of the products, and dealing with the accounts payable workforce to finish the seller cost related to the bill that matches the transaction.

The way to Optimize your Supply-to-Pay Course of?

Implementing a sturdy and optimized S2P system entails –

- use of automation to automate the procure-to-pay a part of the source-to-pay course of (optimizes steps 7-10)

- bettering provider relationship administration. (optimizes steps 1-6)

Let’s discover each intimately.

1. P2P automation

Like most enterprise processes at the moment, navigating the supply to pay course of with the appropriate S2P software program resolution has quite a few advantages. Though the steps have stayed comparatively the identical, the way in which the steps are accomplished has shifted with the usage of automation know-how.

Right here is how P2P automation with a software program like Nanonets streamlines every step within the procure-to-pay a part of the S2P course of.

Making a Buy Request

When an worker must make a purchase order, they merely log into the Nanonets portal and submit a digital buy request.

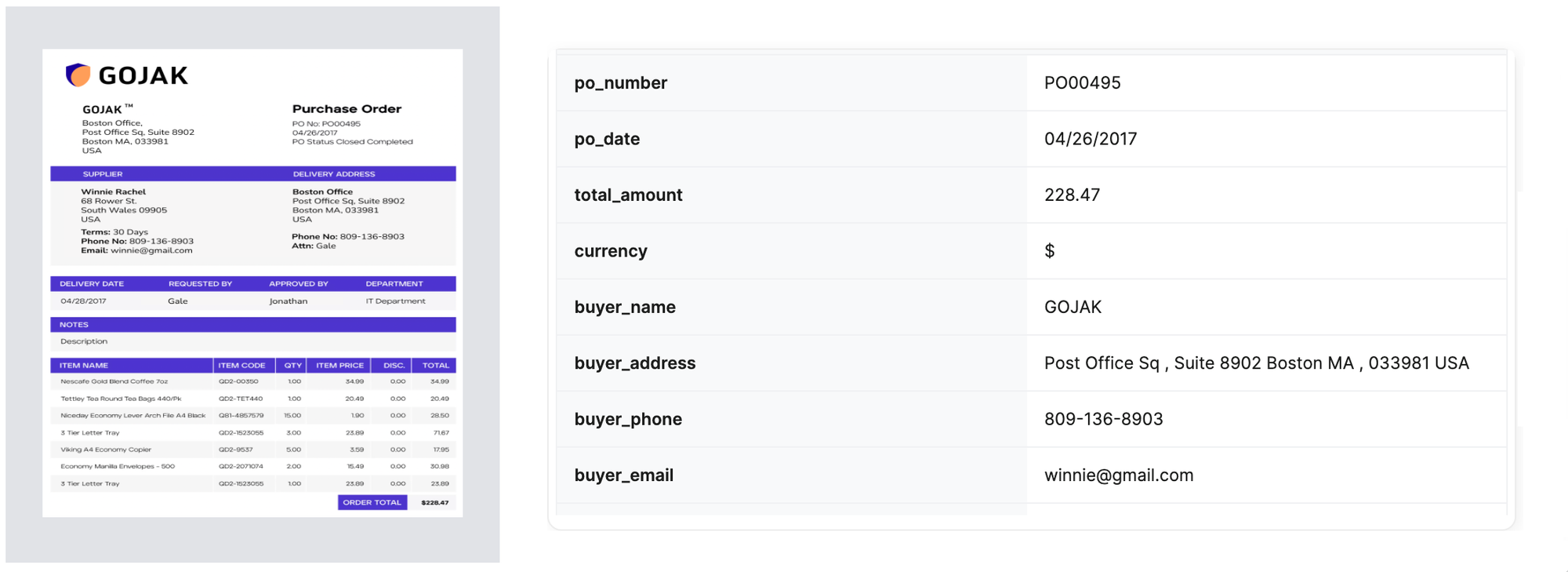

Making a Buy Order

Nanonets takes care of the paperwork by mechanically producing a Buy Order (PO) based mostly on the small print supplied within the request.

Approval for the Buy Order

The PO goes by way of an automatic approval course of inside Nanonets. You may arrange guidelines and circumstances to make sure consistency throughout procurement actions, avoiding errors and unauthorized bills.

You will obtain approval notifications that may be simply managed by way of standard communication instruments like Slack and Microsoft Groups. They even include direct Name To Actions (CTAs) that can assist you make fast choices.

Sending out the Buy Order

As soon as the PO is accredited, the system takes care of sending it to the provider. This may be accomplished by way of built-in e-mail or provider portals like SAP Ariba or Coupa.

.png)

Monitoring Items or Companies Supply

The provider takes care of processing the order and updating the supply standing of their portal. This info is mechanically synced with Nanonets, so you possibly can simply monitor the progress.

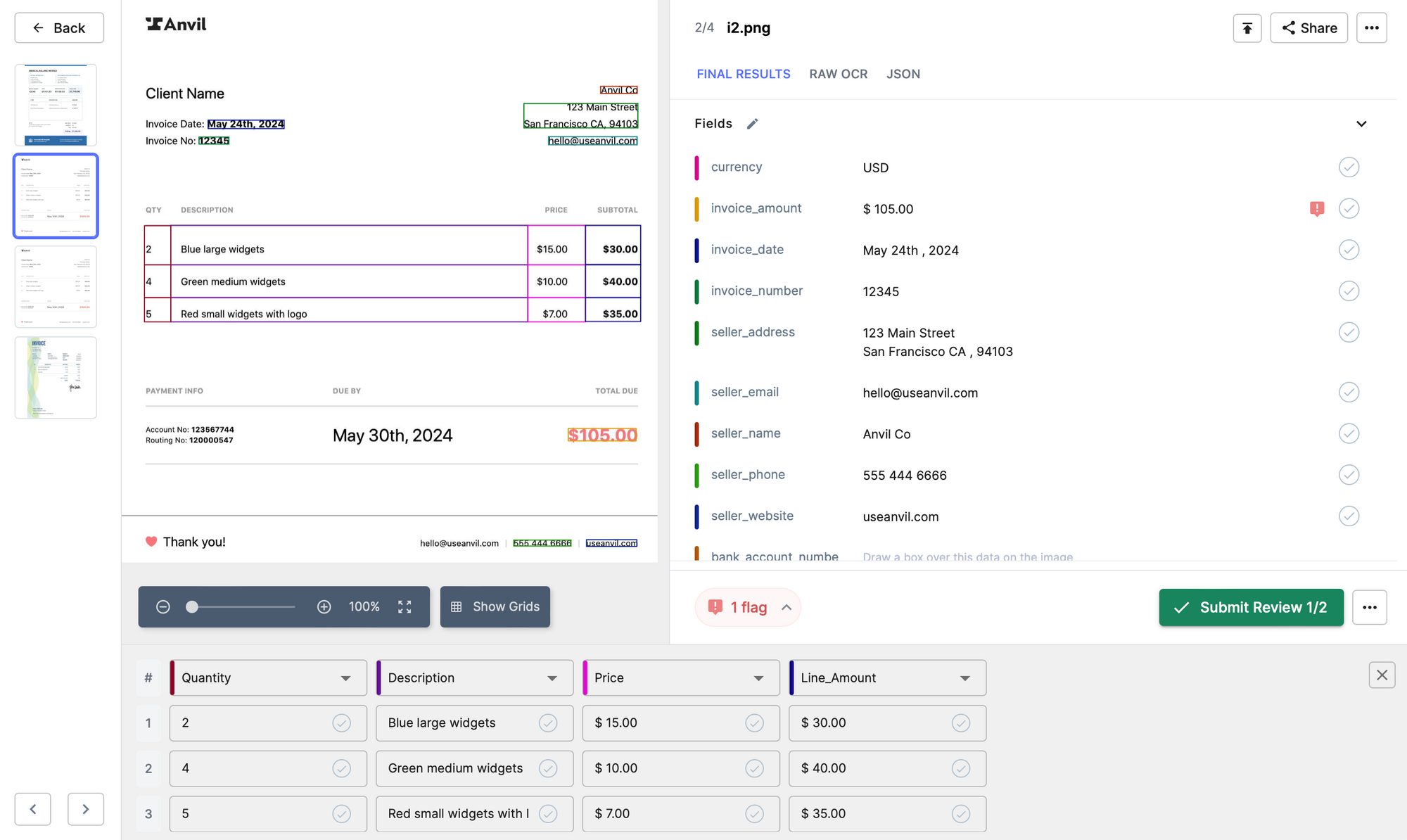

Capturing and Matching Bill Information

Nanonets does the heavy lifting by mechanically extracting knowledge from invoices, buy orders, and supply notes. This protects you from guide knowledge entry and reduces errors.

To make sure accuracy, the system performs automated three-way matching. It verifies that the invoices, buy orders, and supply notes align earlier than processing funds.

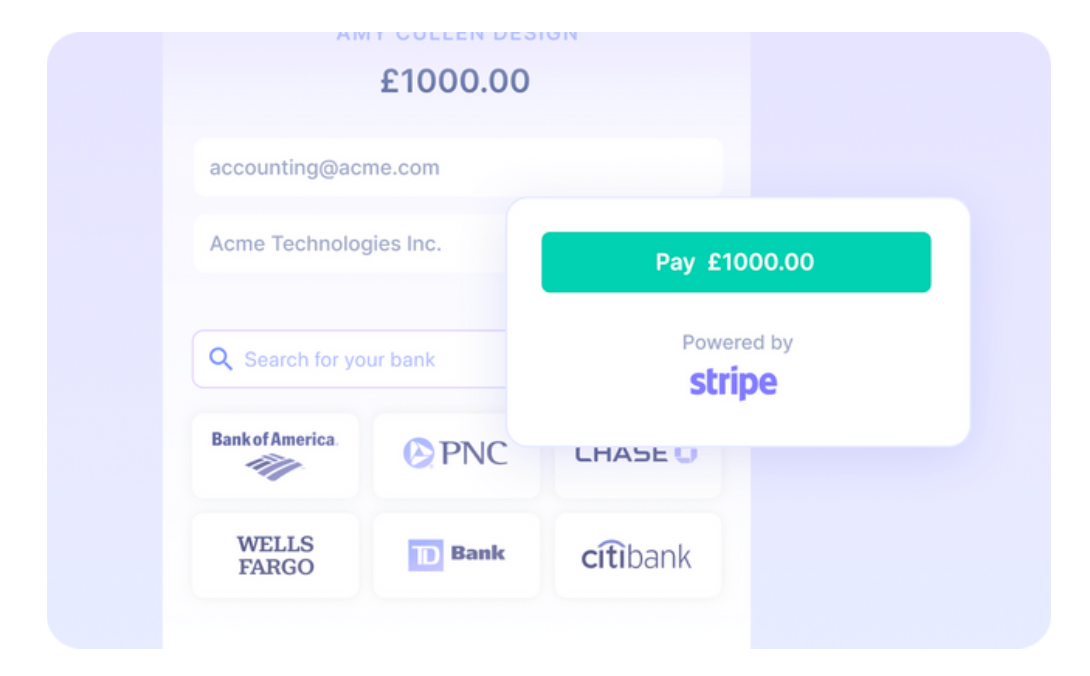

Processing Funds

Nanonets streamlines the cost course of, ensuring all transactions are accomplished effectively and on time. This helps preserve good relationships with suppliers and avoids late cost penalties.

Integration with ERP/Accounting Software program

Nanonets seamlessly integrates with totally different ERP and accounting techniques. This offers a unified expertise for managing procurement and monetary knowledge.

2. Provider Relationship Administration

Efficient Provider Relationship Administration (SRM) is essential for sustaining easy relations together with your suppliers, the significance of which is paramount for a streamlined S2P course of.

For one, companies can use contract administration software program to retailer and handle all provider contracts. One can arrange alerts for key dates equivalent to renewal deadlines or efficiency evaluations to make sure well timed motion.

Additionally, Provider Efficiency Administration (SPM) is a superb device to optimize the S2P course of additional. When accomplished successfully, SPM can convey a number of advantages to your small business:

- Increase provider efficiency and reliability.

- Cut back the danger of provider points and stop disruptions in your provide chain.

- Safe higher pricing.

- Enhance high quality and compliance requirements.

You may implement SPM in your provide chain processes by integrating the next steps:

Step 1: Phase Suppliers and Use Filters

Each provider is exclusive and has a unique impression in your firm. To make issues simpler, categorize them based mostly on their significance, equivalent to vital, necessary, and people with minimal impression. This fashion, you possibly can prioritize your efforts and assets extra successfully.

If you wish to study extra about figuring out key suppliers, try this useful resource: Key Suppliers | Establish & Handle Key Distributors & Suppliers

Step 2: Outline Efficiency Measures

To maintain issues clear and measurable, set up efficiency metrics in your suppliers. Some frequent metrics embody supply efficiency, high quality requirements, regulatory compliance, and cost-effectiveness.

For extra info on provider efficiency measures, you possibly can learn this text: What are provider efficiency measures?

Step 3: Preserve a Provider Scorecard

Create a provider scorecard to maintain monitor of and consider provider efficiency based mostly on the outlined metrics. Bear in mind, this ought to be a dynamic doc that you just replace frequently with the most recent efficiency knowledge.

Step 4: Conduct Common Efficiency Critiques

Recurrently assessment the efficiency of your vital suppliers. Use the info out of your scorecard to have significant discussions about their efficiency, handle any points, and determine alternatives for enchancment.

Step 5: Negotiate Higher Phrases

Make the most of the insights you achieve from SPM to barter improved phrases together with your suppliers. Use particular knowledge to spotlight areas the place they’ll enhance, and suggest mutually helpful modifications to your contracts.

For extra tips about negotiating higher cost phrases, try this useful resource: 7 Suggestions for Negotiating Higher Cost Phrases With Your Suppliers

By following these steps, you’ll implement a sturdy SPM system that enhances provider efficiency, reduces dangers, and finally drives higher enterprise outcomes.

Closing Ideas

Should you run an workplace provide retailer and might’t appear to maintain notebooks stocked as a result of your S2P workforce is failing, you could possibly very nicely exit of enterprise.

Though we take a look at the S2P course of holistically, enchancment alternatives could be discovered when drilling into every operate’s duties and performance.

Know-how is part of enterprise at the moment, it doesn’t matter what trade you’re working in. In the present day, companies can fold know-how into processes like S2P to make the lives of their workers simpler, construct higher partnerships externally, and get essentially the most bang for the buck.

Should you’re unsure the place to start out, implementing a supply to pay system like Nanonets is the proper place to get began. Schedule a custom-made demo at the moment!

[ad_2]