[ad_1]

Written in collaboration with Navin Sharma and Joe Pindell, Stardog

Throughout industries, the affect of post-delivery failure prices (recollects, guarantee claims, misplaced goodwill after supply) may be huge. Within the meals trade, the typical value may be over $10M per occasion in direct prices. The affect is commonly multi-dimensional, resulting from misplaced gross sales and model popularity damages. In accordance with some estimates, the misplaced gross sales from post-delivery failures is equal to over 2,000 instances the typical income per buyer. Insufficient resolutions and gradual responsiveness to prospects, notably in high-stakes conditions like this, could make them churn to competitors, slicing off the oxygen that fuels future progress. Thus, it’s no shock that the price of poor high quality is a major monetary burden to manufacturing corporations, and in some instances can value corporations as much as 40% of working prices.

Whereas corporations want they might have extra early warning indicators of impending high quality points, often, corporations solely get to know after the very fact, pushed by an uptick in buyer complaints which can be continually being monitored by the group. A typical problem appears like this: over the weekend, the variety of customer-reported points from the sector spikes and reviews are signaling product high quality points and dissatisfaction with the model. When it’s in impact, a state of affairs like that is certainly a hearth drill. Prospects not merely settle for longer lead instances for response and demand an elevated commonplace to cope with such points.

Creating a New Strategy to Play with Databricks & Stardog

As most organizations know, high quality points will not be often remoted situations. These are recurring issues that want repeatable options and programs to constantly monitor buyer suggestions, prioritize pressing points, and drive quicker decision. When hit with a high quality problem, corporations need to acquire a deeper understanding of the scope of the issue, potential secondary impacts, acquire a greater understanding of underlying root causes upstream in manufacturing processes and provide chain, to keep away from expensive points like this sooner or later.

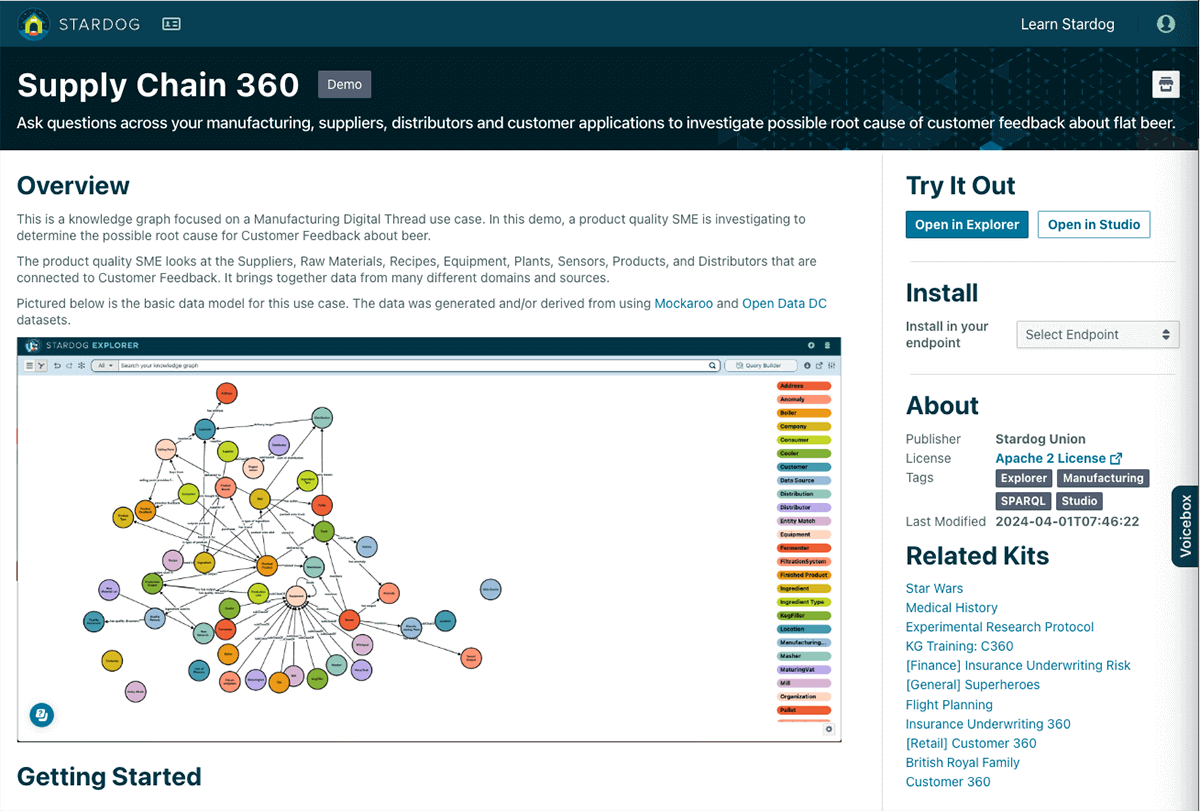

This requires incorporating all disparate information sources to know the a number of interconnections between the completely different information domains and growing the corporate’s data base and programs. Right now, we’ll spotlight the facility of utilizing Stardog’s Generative AI powered by a data graph with Databricks to assist manufacturing organizations to conduct high quality occasion forensics to rapidly determine issues and enhance buyer outcomes.

Stardog Voicebox can determine and hyperlink information related to enterprise objects like vegetation, suppliers, manufacturing processes, logistics, product households, SKUs and so on. This linking functionality supplies higher and quicker selections for manufacturing and provide chain use instances. Moreover, the Stardog platform integrates with Databricks through Associate Join and leverages Databricks to course of information at scale.

To elucidate how Databricks and Stardog will assist corporations construct an end-to-end functionality to higher handle high quality incidents, we are going to take an instance of a beer distributor supplying beer to numerous stadiums throughout sporting occasions. At a excessive profile sport, the corporate begins receiving reviews that numerous followers are discovering the beer to be “flat” – setting a sequence of occasions in movement.

Execute Fast High quality Occasion Forensics

In terms of high quality points, time will not be your good friend, and neither is siloed and disconnected information. As a product high quality SME, you need to triage the state of affairs as quick as attainable to be able to deploy the fitting assets to handle the problem at hand, making certain crucial high quality considerations obtain fast consideration.

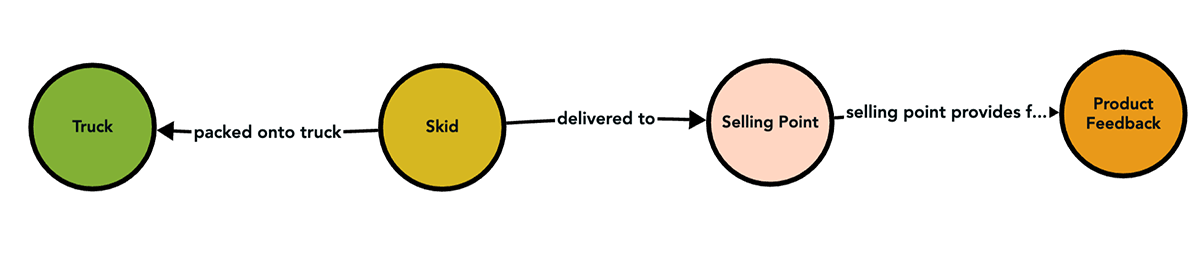

As a product high quality SME, we’d begin with the damaging suggestions to know what the suggestions is, what it is about, and the place it got here from. This may require visibility throughout Product Suggestions, Completed Merchandise, Promoting Factors, Stadiums, Distributors, Vehicles, Sensors, Pallets, and Suppliers. This brings collectively information from many various domains and sources.

Stardog is a data graph platform that permits companies to attach and question information in a versatile and interconnected method. This makes it preferrred for buyer and product help, because it permits us to rapidly and simply discover the knowledge we have to analysis these buyer points. This makes it simple for different buyer help brokers to seek out the knowledge they should resolve buyer points, in pure language, even when they don’t seem to be accustomed to the underlying information construction.

A novel function of a Stardog data graph is the flexibility to outline guidelines that apply to the info at question time. Reasoning permits Stardog’s Inference Engine to affiliate associated info to deduce new connections. These guidelines don’t create any new information however assist you to work together with them as in the event that they have been precise information. The Anomaly idea under is one thing that you simply will not discover outlined or saved explicitly wherever within the information. It’s an implied output when the outlined circumstances of the rule are met.

Let us take a look at the rule definition under. As you may see, if any truck has a temperature sensor with any sensor output equal to or larger than 50 levels Fahrenheit, then Stardog’s Inference Engine infers that the truck has an anomaly related to it.

These information shortcuts turn into extremely helpful in serving to the product-quality SMEs of their interrogation. For instance, reasoning infers that Truck 002 has 11 anomalies as a result of it has a temperature sensor that has 11 outputs equal to or larger than 50 levels Fahrenheit. With this discovery, the product high quality SME can see that the temperature distinction on the truck contributed to the flat beer. Whereas that is could also be a superb discovery, it opens the door to much more necessary questions to know the total extent of the issue.

Estimate Blast Radius

An earthquake is often accompanied by a wave of aftershocks, and that is additionally true within the case of product high quality points. Estimating the potential scope of a high quality problem includes assessing its potential affect on different batches of the identical product, related merchandise or on this case associated venues. Since we have traced the issue all the way down to a selected automobile, we have to assess the potential downstream affect which may have an effect on different prospects.

Let’s dig in slightly additional on Truck 002 and see if it is headed wherever else. A fast dialog with Stardog Voicebox exhibits us the Truck 002 is scheduled for 2 supply places.

Since we all know from our troubleshooting that the unique complaints got here from Wrigley Area, we should always flip our consideration to alerting the personnel at Indianapolis Motor Speedway in regards to the flat beer. At a minimal, they need to examine the product earlier than serving to forestall further damaging reviews. Within the occasion they’ve a scarcity, then we would have the ability to discover an alternate truck with the identical product, or worst case, provide prospects a coupon.

By evaluating all doubtlessly associated circumstances, companies can estimate the blast radius of a product problem and proactively make selections to handle it. This may occasionally contain implementing mitigation methods reminiscent of product recollects, software program updates, or manufacturing course of changes to reduce the affect on prospects.

Traceability to Manufacturing and Provide Chain Points

Tracing again to manufacturing and provide chain points is a crucial step in resolving issues. By figuring out the basis causes of points and taking corrective actions, corporations can develop more practical options and forestall recurring points. This may occasionally contain figuring out with suppliers to enhance high quality, discovering different sources of provide, or making adjustments to manufacturing processes.

Provide chain visibility is essential for any manufacturing group looking for to enhance experiences and outcomes, however lower than 6% of organizations are there right this moment. The Databricks Knowledge Intelligence Platform constructed on the Lakehouse structure, coupled with Stardog as a semantic layer – permits corporations to construct a extra linked view of their information and the relationships between them. This may be an immense benefit for coping with provide chain challenges, reminiscent of high quality occasion forensics, that calls for a complete, linked view throughout datasets – which finally permits manufacturing corporations to drive data-driven selections.

Get Began Right now!

Unlock the potential of Stardog right this moment by visiting the Databricks Associate Join web site. Comply with the step-by-step directions offered within the Stardog documentation to attach Stardog with Databricks. As soon as linked, you’ll acquire entry to the Provide Chain 360 data equipment, a complete useful resource containing the whole lot you could observe the instance above.

[ad_2]